Bought plasma cutting machine and large multifunctional laser cutting machine

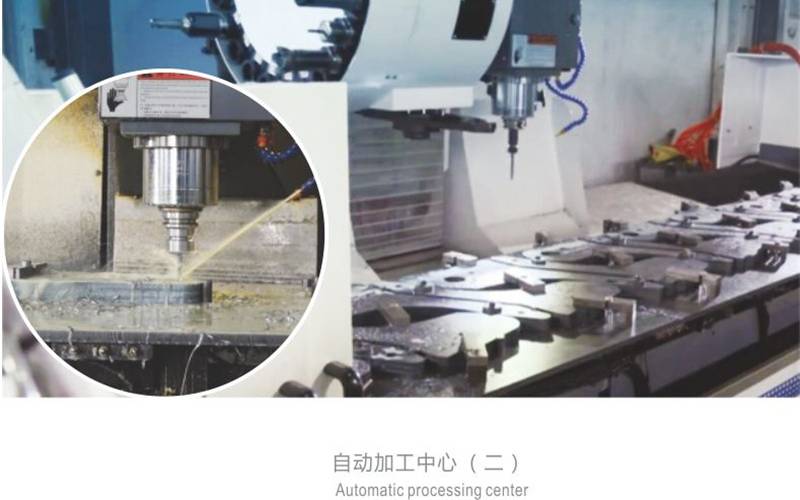

Introduced various processing center to refine he hardware of various parts

Started using 3 robotic intelligent welding machines

Invested in large injunction molding machine and developed semi-automatic chair frame assembly line

Enhanced digital processing center and laser cutting machine

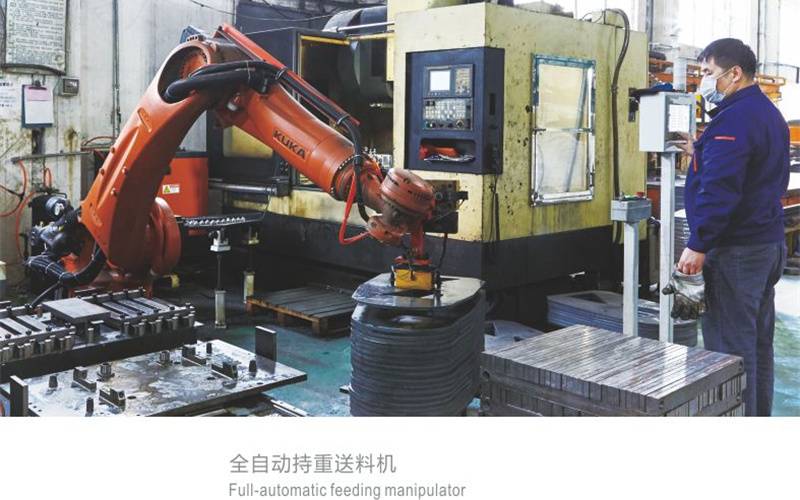

Manipulation for automatic loading and uploading put into use

Eight new German KUKA manipulator automatic assembly system has the advantage of high precision, fast speed, stable production quality and capacity

We believe that technical strength is one of the main strength to maintain the product's stability & durability, ANYE has over 10+ person Technical department with more than 20 years of experience in designing dental units. ANYE products are in line with the ergonomic streamline design which can automatically cooperate with cushion movement to form an elevation angle.

1. Ensure the qualification rate of each component increase to 99%. From raw materials to finished products, we use advanced automation equipment in the industry for processing. (e.g. laser machine,KUKA Robot manipulators, automatic processing center, etc.)

2. All of ANYE’s valves can used after strict air tightness testing to ensure that the possibility of water leakage and air leakage is minimized of each valve.

3. All components of whole unit have passed the continuous aging test of our self-developed equipment which is an indispensable link to improve the service life of the units. ( e.g. chair frame, motor, LED light , light arm, system, etc. )

4. Anye is the first manufacturer in the industry to use automated equipment to manufacturing dental units. we can guarantee the same technics and the same quality when we manufacturing one set of equipment or even ten thousand.

We see service management as an integral part of our key strength. Fast service gives a commitment to our clients to get the best service and products.